Expanded Waterworks Solutions

Email our sales team sales@controlvalves.com for more information!

Pressure Reducing

- Regulates at a stable mode, regardless of valve size, down to near-zero flow, eliminating the need for a special low flow feature or a bypass valve

- Includes a self-flushing, inline control filter to reduce periodic inspection/maintenance costs

Flow Modulated Pressure Reducing Valve

- Reduces upstream pressure to a downstream pressure that increases or decreases simultaneously with the demand flow

- The pressure into the zone is continually adjusted according to the zone’s actual demand, thus compensating for the system loss

- The pressure flow profile can be adjusted to control from no flow, to maximum full open flow without any chattering or slamming

- Hydraulic water saving solution

Pressure Sustaining Valve

- Modulates to maintain a steady pressure in the network upstream of its location

- Includes a self-flushing, inline control filter to reduce periodic inspection/maintenance costs

Pressure Sustaining & Relief Valve

- Maintains upstream pressure, regardless of flow rate variations and relieves pump surplus flow from the system, thus preventing high pressure at low demand conditions

- Includes a self-flushing, inline control filter to reduce periodic inspection/maintenance costs

- Exceptionally low losses at high flow

Surge Anticipation With Bonnet Accelerator

- Protects the pumping system from water hammer resulting from sudden pump shut-off

- High and low pressure relief

Flow Control Valve

- Limits the flow rate in the network to a preset value regardless of upstream pressure variations. The valve fully opens when the flow rate drops below the set point

- Regulates at a stable mode, regardless of valve size, down to near-zero flow, eliminating the need for a special low flow or a bypass valve

- Includes a self-flushing, inline control filter to reduce periodic inspection/maintenance costs

Two Stage Cushion Closure Check Valve

- Activated by the pressure of the pipeline, the valve eliminates the pressure slam of check valves, frequently found in roof-tank filling pumps of high-rise buildings. It opens on pump start, and closes at a controlled pace when the pump stops

- Includes a self-flushing, inline control filter to reduce periodic inspection/maintenance costs

On/Off Solenoid Control

- A 3-port solenoid valve, activated by an electronic current or an electric pulse, opens or closes the main valve

- Low power electric activation

- Quick response

- Can be added as electric override to any other control function

Altitude Control

- Controls the water volume in an elevated tank

- Accurate and repeatable differential level control

- Quick response

- Easy access-no float is located in the tank/reservoir

- Adjustable drawdown feature

Electric Float Controlled Valve

- The main valve will fully open when the solenoid is activated via an electric sensor float in the tank/reservoir and will close drip tight when the solenoid deenergized, thus enabling accurate and reliable differential level control

- Low power electric activation

- Fast response

- Optional feature: Stepped Surge-Preventing Closure

Air Valves

- Prevents air pockets from reducing the effective cross-section of a pipeline, thereby maintaining water flow, and saving energy

- Drains air at high flows at very low pressures

- Allows a high flow rate of air into the pipe when it is draining, preventing the excessive negative pressure that may cause the pipe to collapse

- Enables draining of small quantities of air which tend to accumulate in the elevated locations during normal system operation

Accessories

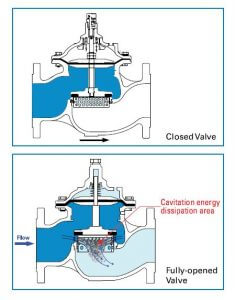

Cavitation Cage

- Enables the valve to operate at any pressure differential without damage to the valve or system

- Cavitation energy is safely inside of the internal cavitation structure, made of stainless steel and connected to the valve below the standard seal disc to move freely inside the seat

- Certified by extensive testing via independent laboratories in US and Europe

Dual Chamber Feature

- Easier changeover

- Creates a second control chamber below the diaphragm, permitting for the activation of the valve in low pressure situations

- Quick response to varying conditions

Visual Indicator-eases air bleeding

Inline Strainer-Self-cleaning and easily removed

New Fire Protection Solutions

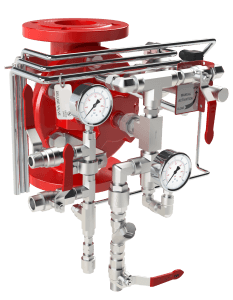

Electrically Actuated Deluge Pressure Reducing Valve

- Designed for high pressure, high flow deluge systems

- Regulates downstream pressure regardless of upstream pressure and flow fluctuations

- Automatic or manual emergency actuation

- Superior design featuring exceptionally low pressure at high flow rates

- Low to negligible lifelong maintenance costs due to no wetted metallic and mechanical moving parts

- Deluge with pressure reducing in a diaphragm style valve

Pneumatically Actuated Deluge Pressure Reducing Valve

- Designed for high pressure, high flow deluge systems

- Regulates downstream pressure regardless of upstream pressure and flow fluctuations

- Automatic or manual emergency actuation

- Superior design featuring exceptionally low pressure losses at high flow rates

- Low to negligible lifelong maintenance costs due to no wetted metallic and mechanical moving parts design

- Deluge with pressure reducing in a diaphragm style valve

Electro-Pneumatically Actuated Deluge Valve

- Designed for high pressure, high flow deluge systems

- Closed in normal set position and opens when the pneumatic pressure drops in a gas pressurized pilot line, releasing a relay, or be an electric command

- Emergency manual release valve is fitted as standard

- Superior design featuring exceptionally low pressure losses at high flow rates

- Low to negligible lifelong maintenance costs due to no wetted metallic and mechanical moving parts design

Manually Actuated Monitor Valve

- Closed in normal set position and open when an activation selector valve, assembled on the cover, is turned to the open position

- Gradually closes drip-tight when the selector valve is turned back to the closed position, preventing water hammer

- Effortless open/close actuation

- Quick response

- Brand new to OCV product line

Hydraulic Pressure Reducing Hydrant Valve

- Manually actuated, allowing the user to open or close the valve quickly and effortlessly, even under high pressure conditions

- Opening and closing rates regulated by inline orifices

- Adjustable pressure set point

- Controlled response

- Brand new to OCV product line

Zero Pressure Foam Concentrate Electrically Actuated Double Chamber Slave Control Valve

- Installed downstream of the foam concentrate tank and is closed in its normal set position by main line pressure. When the valve’s solenoid is actuated it allows the valve to be forced open by the main line pressure. This allows the foam concentrate valve to open even with zero upstream line pressure, ensuring fail safe supply of foam concentrate through the foam proportioner, downstream of the main master valve

- Double chamber zero pressure operated by deluge water mains

- Electric remote actuation and remote reset, manual emergency actuation

- Brand new to OCV product line