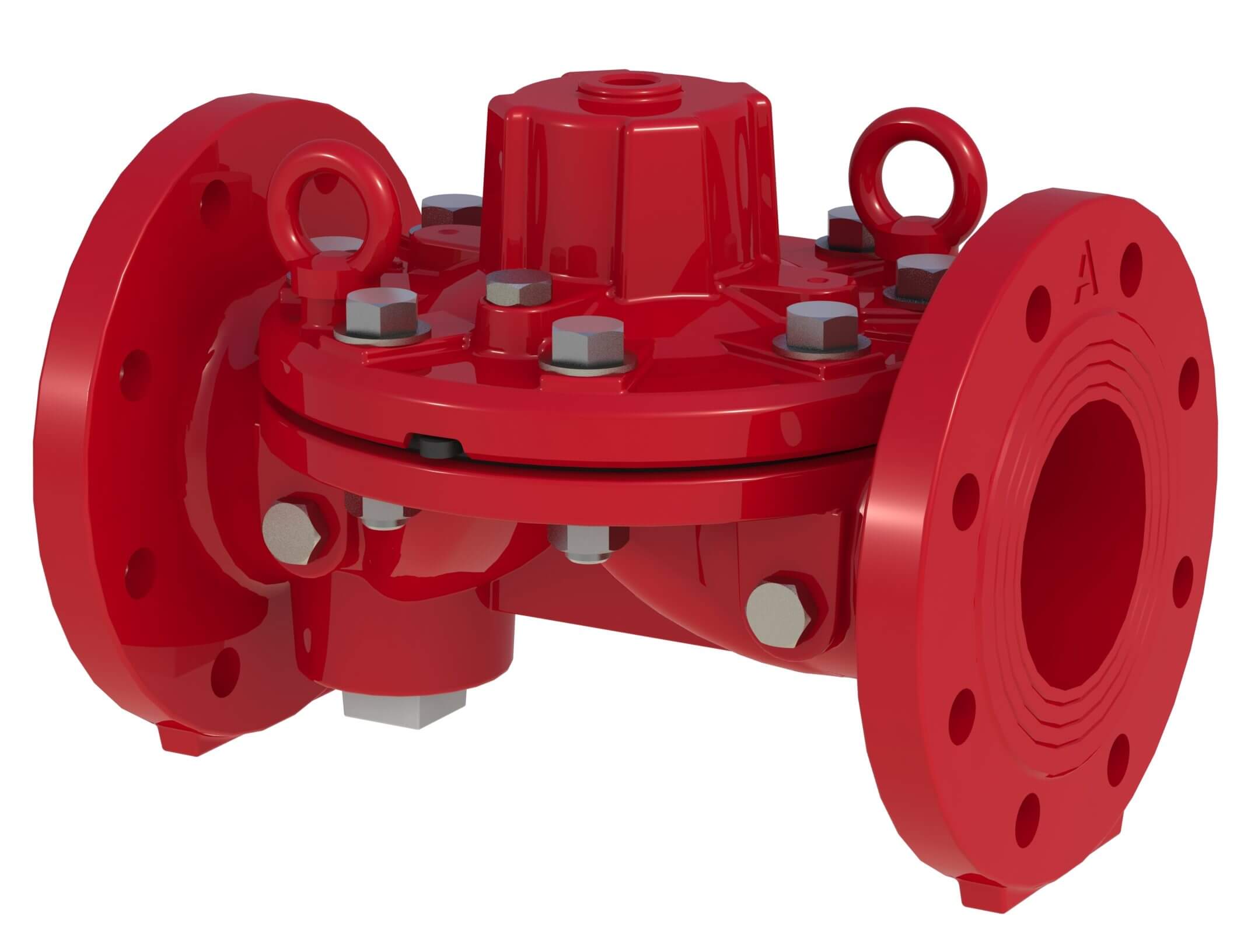

The OCV Series 100 control valves are automatic, hydraulically actuated, direct diaphragm sealing globe/weir type valves with a proven and reliable design. These valves are designed for use in fire protection applications including deluge, pre-action, pressure relief, monitors, hydrants and are suitable for water, foam and seawater systems. The valves consist of three major components: body, cover and diaphragm assembly.

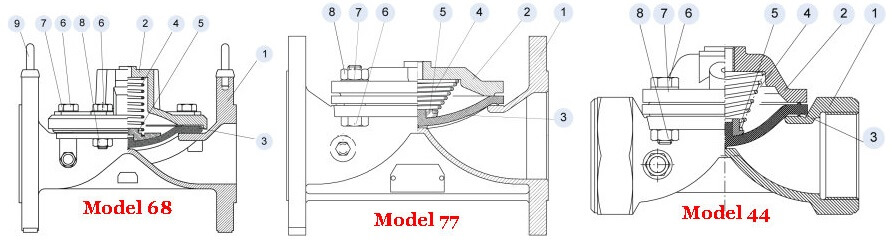

UL Listed basic untrimmed valve models: 44, 68, 77

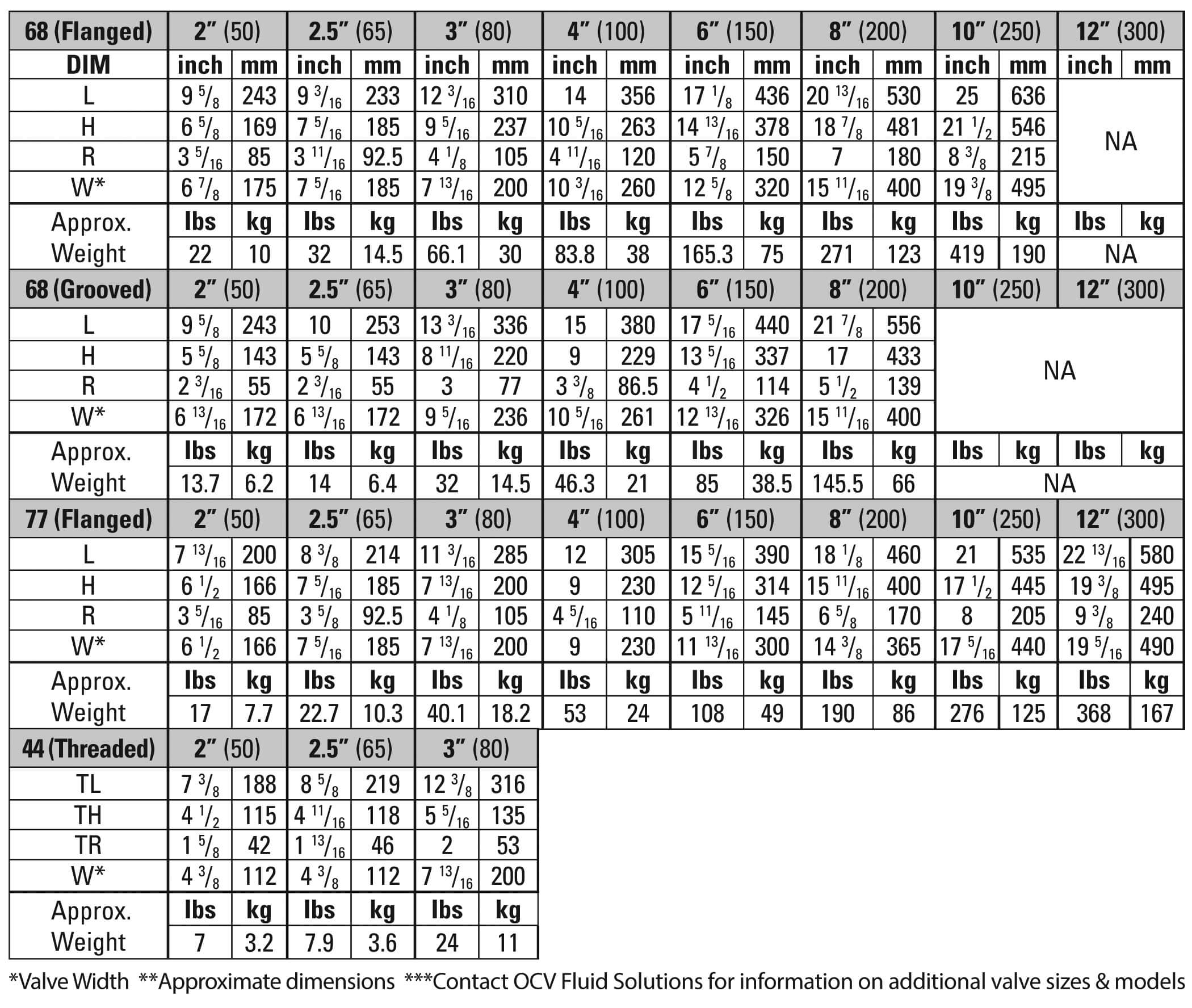

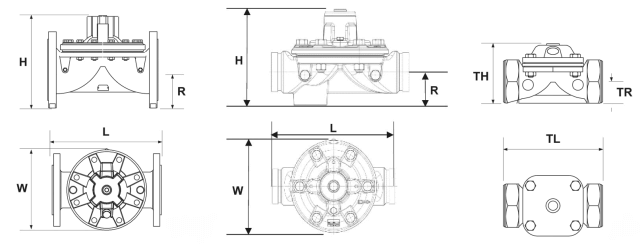

Model 44: Up to 230psi working pressure, threaded.

Model 68: Up to 375psi working pressure, flanged & grooved with drain port.

Model 77: Up to 230psi working pressure, flanged & grooved.

• UL Listed under the following categories:

– “Special Systems Water Control Valves” Deluge (VLFT) – Model 68

– “Fire Pump Pressure Relief Valves” (QXZQ) – Models 44 & 77

• ABS Design assessment & Fire tested to EN ISO 6182-5:2006 – Model 68 2”-6”

• Lloyd’s type approval

• CCCf – Model 68 DE\EL(CN)

• GOST-R

• Manufacture & conformity assessment of pressure equipment & assemblies Directive (97/23/EC / EN1074)

Consult the UL listing guide or contact Aquestia USA for a complete list of approved applications and valve sizes.

STANDARD

• Listed & approved for use in fire protection systems by various global standards

• Quick opening: Non-slam closing operation

• Drip-tight shut off to ANSI FCI 70-2 VI seat leakage class

• Simple and reliable design

• Low lifelong maintenance costs due to straightforward design

• Easy installation and inline maintenance

• High-grade construction materials

• Exceptionally low pressure losses

OPTIONAL

• Remote or manual reset

• Manual, electric, hydraulic, pneumatic and combined control trims

• Explosion proof, SIL redundant solenoids & trim accessories

• Seawater and foam concentrate service

PRESSURE RATING

Recommended nominal system pressure to flange class for typical materials as:

• 250psi nominal system pressure for flanges ANSI B16.42 & ANSI B16.50 Class #150 accordingly.

• 375psi maximal system pressure for flanges ANSI B16.42 & ANSI B16.50 Class #300 accordingly.

SPECIFICATIONS

Temperature:

Sizes:

End Connections:

Body & Cover Material:

Coating Material:

Optional Coating Material:

Internal Trim Material:

Elastomers:

Control Trim & Accessories:

Optional Components: